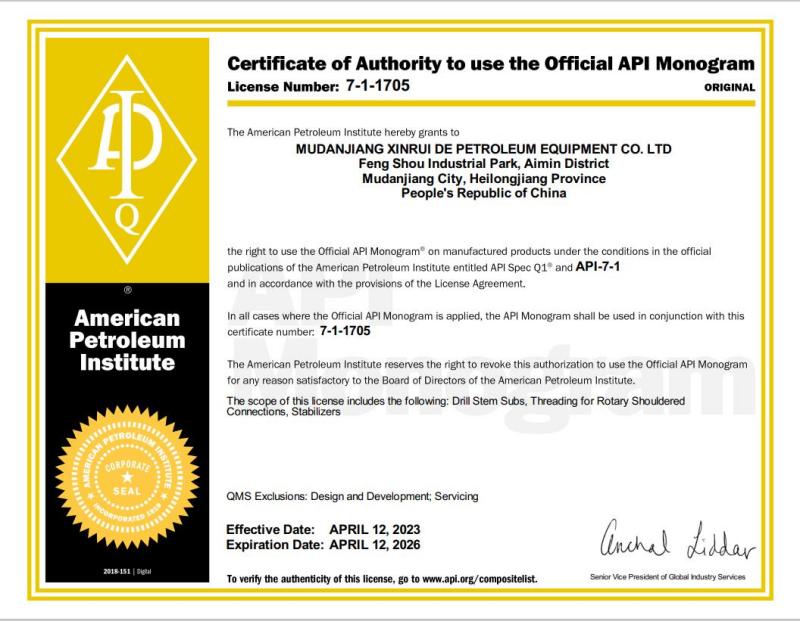

Mudanjiang Xinruide Petroleum Equipment Co., Ltd. was established In 2019. Our company covers an area of more than 10,000 square meters and has more than 100 employees, we mainly manufactures oil & gas down hole equipment, including drilling jars, fishing tools, milling tools, valves, stabilizer, drill collar, drill pipe and etc, which are manufactured strictly following API & ISO and oil & natural gas industry standards.

In the field of production, the company has advanced production facilities and strict quality control system to ensure that each product has excellent performance and reliable quality.

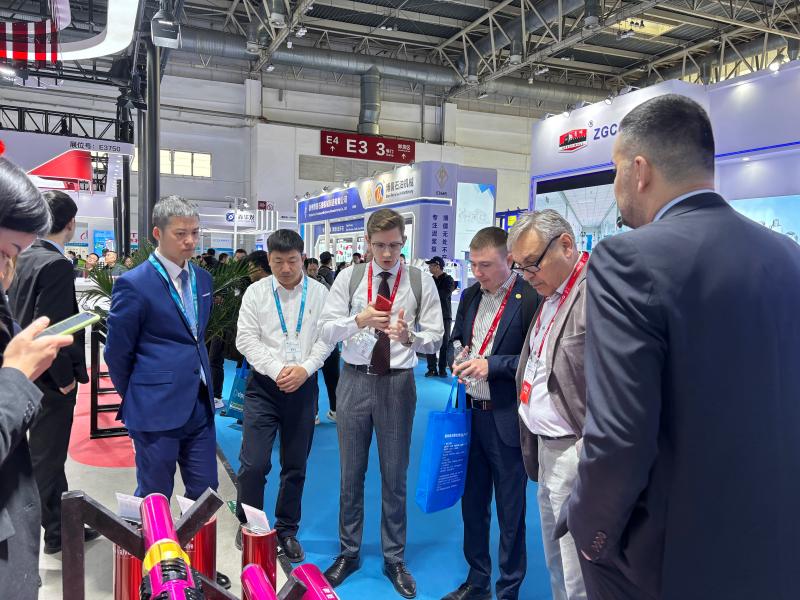

In terms of sales, the company has established a nationwide sales network while actively expanding into international markets, successfully exporting its products to regions such as Europe, the Americas, the Middle East, and Southeast Asia.

The company has entered a stage of rapid growth. The company's product line has been continuously enriched, covering a number of petroleum tool series, forming a relatively complete product system.

Mudanjiang Xinruide Petroleum Equipment Co., Ltd. always puts customer needs in the first place, pays attention to communication with customers, and listens to customers' opinions and suggestions.

More