Product highlights:

➤ Heavy Debris Solution: Catches junks too heavy for fluid circulation (e.g., carbide teeth, bearings, bit fragments).

➤ Wellbore Guardian: Prevents debris settlement at bottom hole, protecting drill bits & BHA.

➤ Optimized Fluid Dynamics: Patented swirl-flow design maximizes junk capture efficiency.

➤ Rig-Ready Robustness:Forged alloy construction for extreme downhole conditions.

➤ Critical Fishing Tool: Integrates seamlessly with fishing tools assemblies for complex recovery ops.

Overview of Junk Sub:

The Junk Sub is a mission-critical oil tool engineered to clean wellbores by capturing heavy debris that conventional fluid circulation cannot remove. Its innovative dual-diameter design features:

- An enlarged external bowl that restricts annular flow, directing 90%+ fluid through the cup.

- A wider mandrel diameter at the cup mouth creating accelerated swirl flow.

- A sudden capacity reduction at the base generating a vortex effect.

This hydrodynamic system forces heavy objects (e.g., drill bit fragments, carbide teeth, bearings) to drop into the cup for retrieval, ensuring a clean bottom hole and protecting downhole assets.

Advantages of Junk Sub:

1. Drill Bit & BHA Protection:

- Extends drill bit service life by eliminating abrasive junk at well bottom.

- Prevents catastrophic damage to drilling tools from unexpected debris impacts.

2. Superior Debris Capture:

- Targets metal fragments 10-50x heavier than fluid-circulatable particles.

- Proven effectiveness in high-risk scenarios: lost cones, bearing failures, milled cuttings.

3. Operational Efficiency:

- Reduces non-productive time (NPT) by eliminating trips for junk-related failures.

- Integrates with standard fishing tools strings for seamless intervention.

4. Engineered Reliability:

- High-yield steel construction withstands 20,000+ psi wellbore pressures.

- Minimal pressure drop design maintains mud circulation integrity.

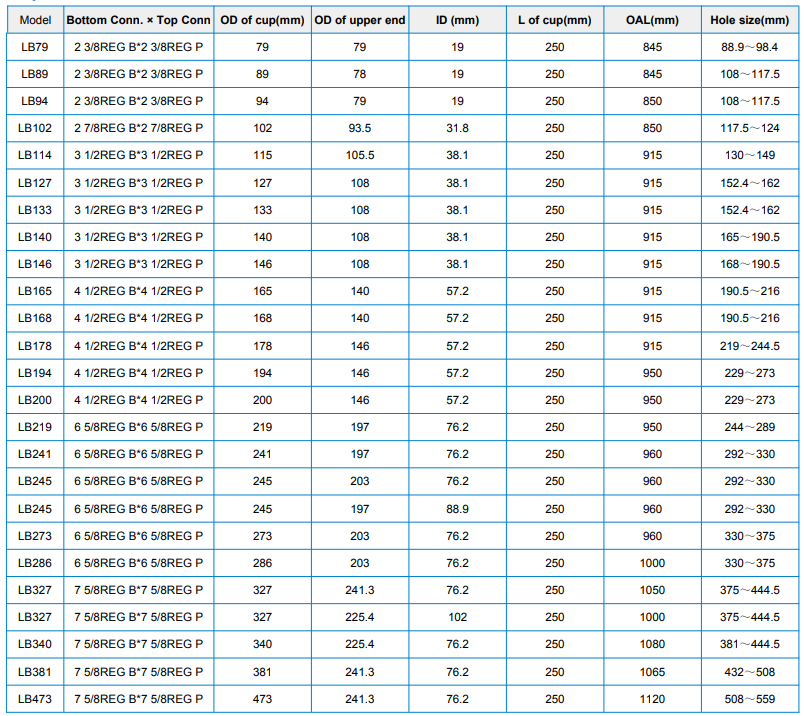

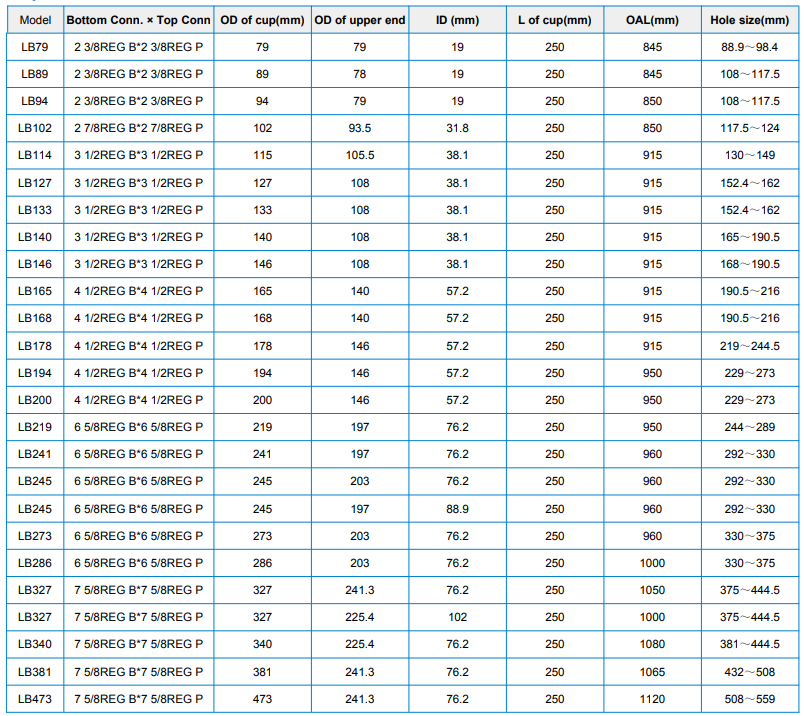

Technical parameters and customization options:

Why choose our Junk Sub?

Professional oil tools manufacturer, strictly following API standards.

Junk Sub adopts precision machining to ensure high-precision matching.

Customized service to meet the needs of different drilling conditions.

Global oil field application verification, reliability and durability are highly recognized.