Product highlights:

1. Dual-Position Deployment

- Configurable as upper or lower valve based on BHA requirements

- Standard API connections (NC50, 6-5/8" REG) for seamless integration with drilling tools

2. Full-Bore Design

- Minimal flow restriction during drilling (ID matches drill stem)

- Tungsten carbide-coated ball reserves erosion from abrasive muds

3. Lifting & Handling Ready

- Forged AISI 4130 body with machined lifting shoulders

- Compatible with standard oil tools

handling equipment

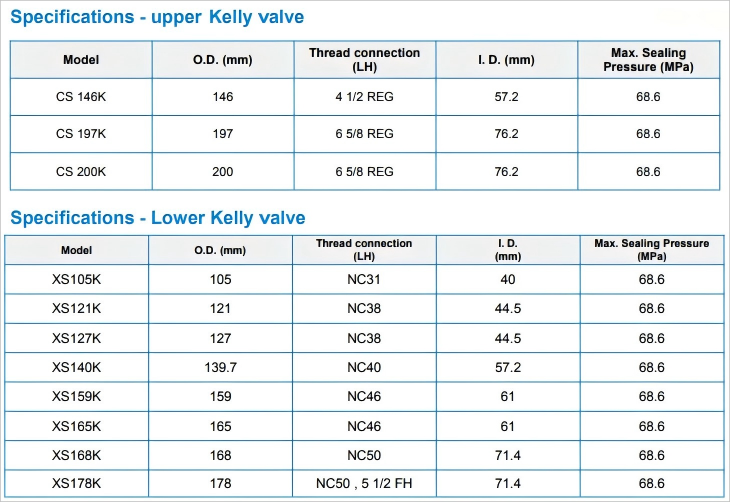

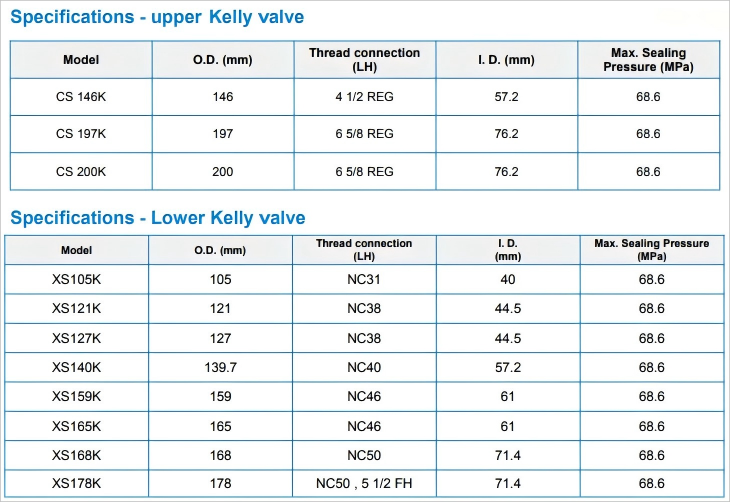

Overview of Kelly Valve:

The Kelly Valve is a critical manually operated ball valve integrated into the drill stem, serving as an emergency well control barrier. This essential petroleum equipment is divided into upper and lower sections:

- Upper Kelly Valve: Installed between the swivel’s lower end and the kelly’s upper end

- Lower Kelly Valve: Connected between the drill pipe’s upper end and the kelly’s (or kelly saver sub’s) lower end

As fundamental drilling tools, these valves enable rapid isolation of the drill string during kicks or blowouts, protecting personnel and rig assets.

Advantages of Kelly Valve:

✅ Emergency Well Control> In case of kick or blowout, turn operating stem to ‘OFF’ position to instantly isolate the drill string, preventing uncontrolled flow.

✅ Fail-Safe Sealing Reliability

> Spring pressure ensures constant ball/seat engagement – the force provided by the spring keeps the ball securely in place even

under vibration.

✅ Operational Continuity

> Maintains unblocked flow during normal drilling when in "ON" position; no pressure drop.

✅ Rapid Response

> Manual operation requires no power – critical when rig systems fail during kicks.

✅ Rig Floor Safety

> Provides accessible pressure barrier closer to surface than BOP stack.

✅ Durability in Extreme Conditions

> Hard-faced seats withstand 500+ cycles in HP/HT environments.

Technical parameters and customization options:

Why choose our Kelly Valve?

Professional oil tools manufacturer, strictly following API standards.

Kelly Valve adopts precision machining to ensure high-precision matching.

Customized service to meet the needs of different drilling conditions.

Global oil field application verification, reliability and durability are highly recognized.