Product highlights:

- API Standard Compliance: Manufactured to meet API mill test pressure specifications for reliable performance.

- Versatile Application: Compatible with drilling tools and oil tools, ensuring seamless integration into testing operations.

- Durable Construction: Reinforced cup design for extended service life in high-pressure environments.

Overview of Cup Tester:The XINRUIDE Cup Tester is a critical pressure testing tool used to verify the integrity of BOP stacks and wellheads by sealing inside the casing below the wellhead. When attached to the drill string, the Cup Tester is lowered into position, filled with water,

and pressurized using a test pump or hoisting mechanism. This method ensures quick and accurate pressure testing, making it

an essential tool for drilling and well control operations.

Designed for oil tools and drilling tools applications, the Cup Tester is built to withstand extreme pressures, with reinforced options

available for demanding well conditions. Its compliance with API standards guarantees reliability in critical well control scenarios.

Advantages of Cup Tester:

1. Efficient Pressure Testing

- Delivers fast and accurate results, minimizing downtime during well testing.

2. High-Pressure Capability

- Standard rating up to 10,000 psi, with reinforced models handling 15,000 psi for extreme conditions.

3. Durable & Reliable

- Reinforced cup design ensures longevity even under repeated high-pressure cycles.

4. API-Compliant Performance

- Manufactured to API mill test pressure standards for dependable operation.

5. Easy Integration

- Works seamlessly with standard drilling tools and oil tools, requiring no special modifications.

6. Versatile Use Cases

- Ideal for BOP stack testing, wellhead integrity checks, and casing pressure validation.

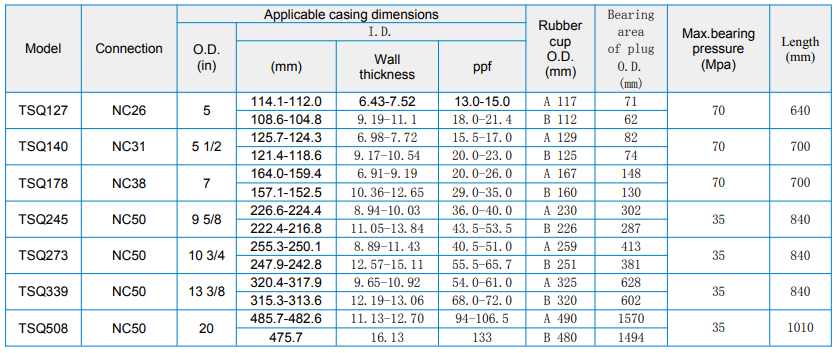

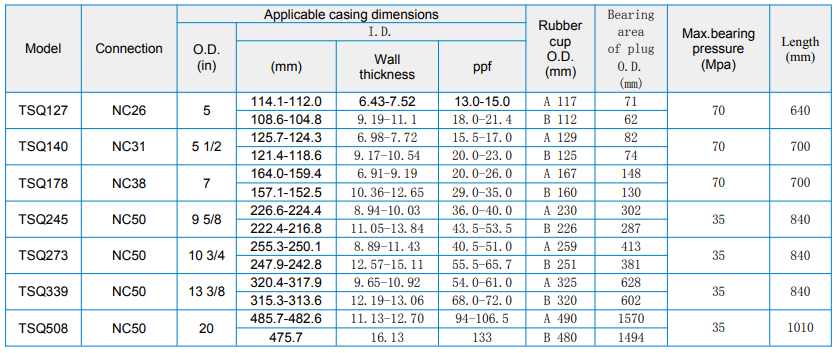

Technical parameters and customization options:

Why choose our Cup Tester?

Professional oil tools manufacturer, strictly following API standards.

Cup Tester adopts precision machining to ensure high-precision matching.

Customized service to meet the needs of different drilling conditions.

Global oil field application verification, reliability and durability are highly recognized.