Product highlights:

➤ Ultimate Metal Capture: The most effective means of trapping metal particles bypassing shale shakers.

➤ Full-Spectrum Protection: Safeguards mud pumps, drill bits & critical drilling tools from abrasive wear.

➤ Milling Operation Essential:Critical for removing mill cuttings and debris during downhole operations.

➤ High-Power Compact Design: Rugged construction with exceptional magnetic field strength and power-to-weight ratio.

➤ Multi-Operation Versatility: Equally effective during washover, fishing, and routine drilling.

Overview of Ditch Magnet:

The Ditch Magnet is a fundamental oil tool for maintaining drilling mud purity. Suspended in the mud ditch or shaker discharge via soft line, its high-performance magnet generates a powerful magnetic field that captures all ferrous metal particles unfiltered by primary solids control equipment. This unit actively removes harmful debris that would otherwise recirculate downhole, making it indispensable during milling operations when metal shavings are abundant.

Advantages of Ditch Magnet:

1. Enhanced Equipment Longevity:

- Reduces wear on mud pumps, drill bits, and downstream drilling tools by eliminating abrasive metal contaminants.

- Prevents downhole equipment damage caused by debris reintroduced with drilling mud.

2. Operational Efficiency:

- Critical for milling operations: Captures mill cuttings before they damage surface equipment.

- Optimizes washover and fishing operations by removing interference-causing metal fragments.

3. Robust & Simple Design:

- Rugged, corrosion-resistant construction for harsh drilling environments.

- High power-to-weight ratio enables easy deployment/retrieval.

4. Low-Maintenance Operation:

- Clean with freshwater/saltwater hose when metal accumulation is visible.

- Quick-cleaning mechanism: Pull rod releases magnetic pole body for instant debris shedding.

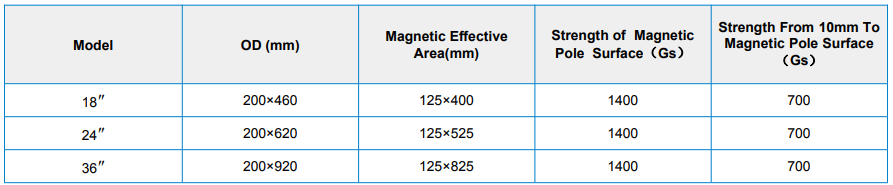

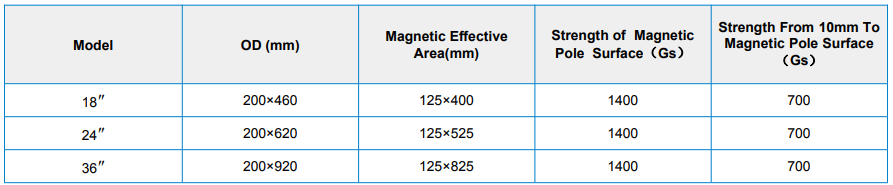

Technical parameters and customization options:

Why choose our Ditch Magnet?

Professional oil tools manufacturer, strictly following API standards.

Ditch Magnet adopts precision machining to ensure high-precision matching.

Customized service to meet the needs of different drilling conditions.

Global oil field application verification, reliability and durability are highly recognized.