Product highlights:

1. Washover Pipe Core Technology

- FJWP Thread™ Connection:

- Two-step double-shoulder design ensures 30% faster makeup vs. standard threads.

- Achieves 98% torsional efficiency (tested to 40,000 ft-lbs).

- Material Science:

- Seamless S-135 steel with anti-galling chrome coating.

-Temperature rating: -20°C to 175°C.

- Hydraulic Optimization:

- ID smooth-bore design maximizes fluid velocity for efficient cuttings removal.

2. Integrated Tool Suite

- Milling Tools:

- Tungsten-carbide mill shoes attach directly to washover pipes for scale/cement removal.

- Reverse-circulation design prevents debris settling.

- Drilling Tools:

- Coring bits with FJWP compatibility for bypassing obstructions.

- Downhole Tools:

- Fishing spears/overshots with FJWP threads for unified intervention strings.

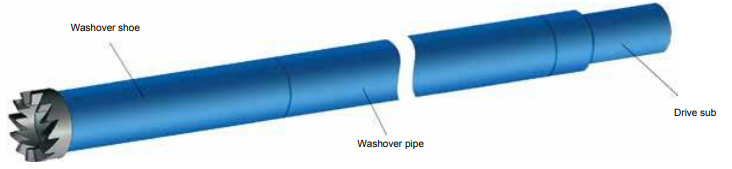

Overview of Washover Pipe:

XINRUIDE’s Washover Pipe System revolutionizes fishing operations by integrating high-torque washover pipes with compatible milling tools, drilling tools, and downhole tools. Engineered to release stuck drill strings in complex wellbores, this system features our proprietary FJWP Thread™ (Two-Step Double Shoulder Connection) for rapid makeup and exceptional torsional strength. Ideal for deviated wells, high-pressure formations, and deepwater operations, it delivers unmatched reliability in critical recovery scenarios.

Advantages of Washover Pipe:

✅ Unmatched Connection Integrity

> FJWP threads eliminate jump-out risks under high torque (API RP 7G validated) → 45% fewer connection failures vs. API threads.

✅ Operational Speed

> Rapid makeup reduces tripping time by 25% – critical in high-cost deepwater wells.

✅ Multi-Threat Intervention

> Unified system handles:

> - Sand/scale accumulation (washover + milling tools)

> - Stuck BHA segments (washover + drilling tools)

> - Metallic obstructions (washover + downhole magnets)

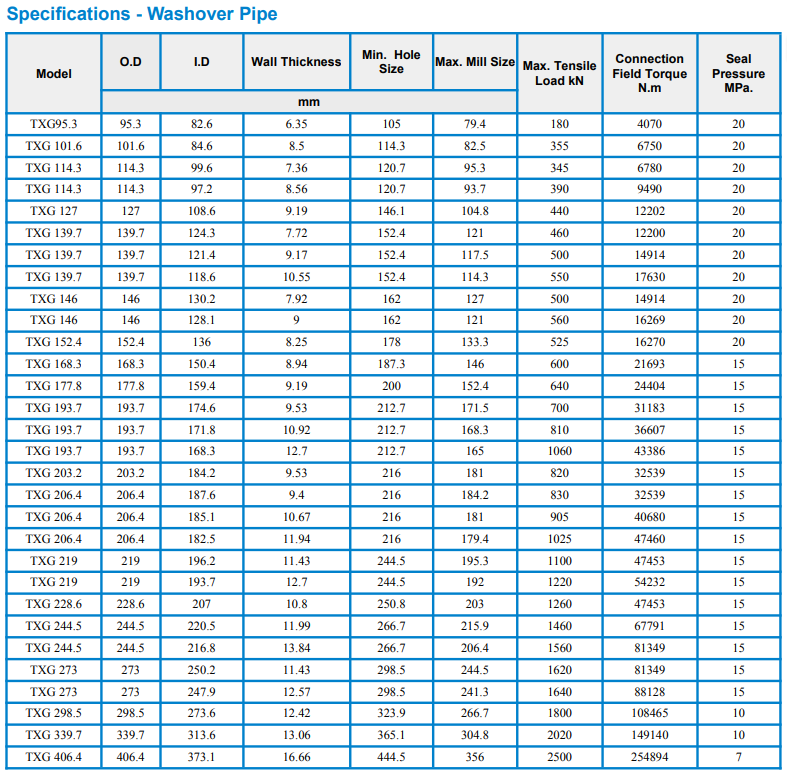

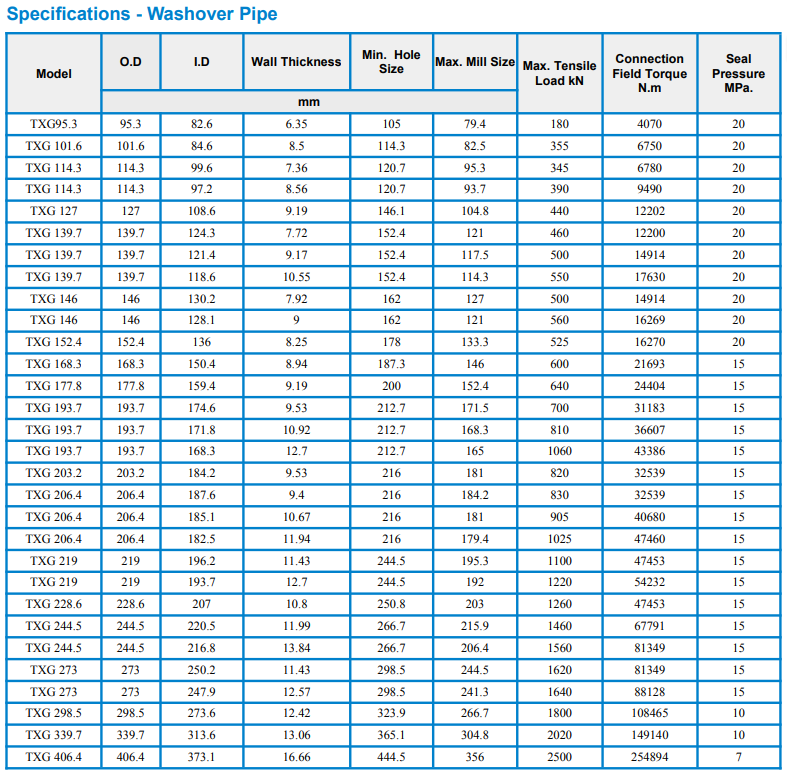

Technical parameters and customization options:

Why choose our Washover Pipe?

Professional oil tools manufacturer, strictly following API standards.

Washover Pipe adopts precision machining to ensure high-precision matching.

Customized service to meet the needs of different drilling conditions.

Global oil field application verification, reliability and durability are highly recognized.