Product highlights:

1. Effective in Sticky Formations:Excels particularly in challenging, sticky formations where conventional tools suffer from severe balling problems.

2. Continuous Cleaning System: Features **three jets with replaceable nozzles** that actively blast the cutting structure.

3. Debris Management: This jet system continuously clears away debris buildup during operation.

4. Enhanced Cutting Efficiency: By preventing balling and clearing debris, the tool maintains a clean, effective cutting structure.

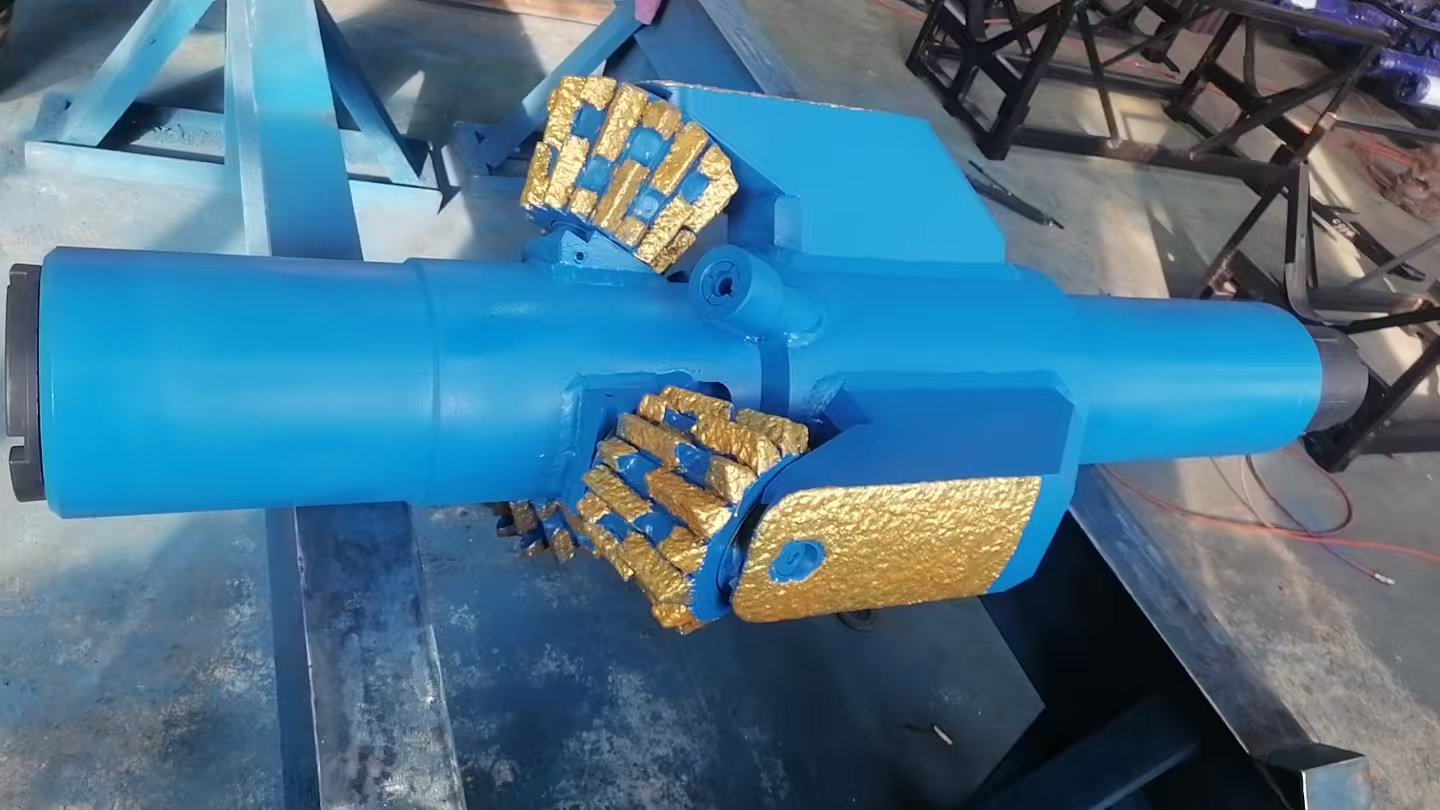

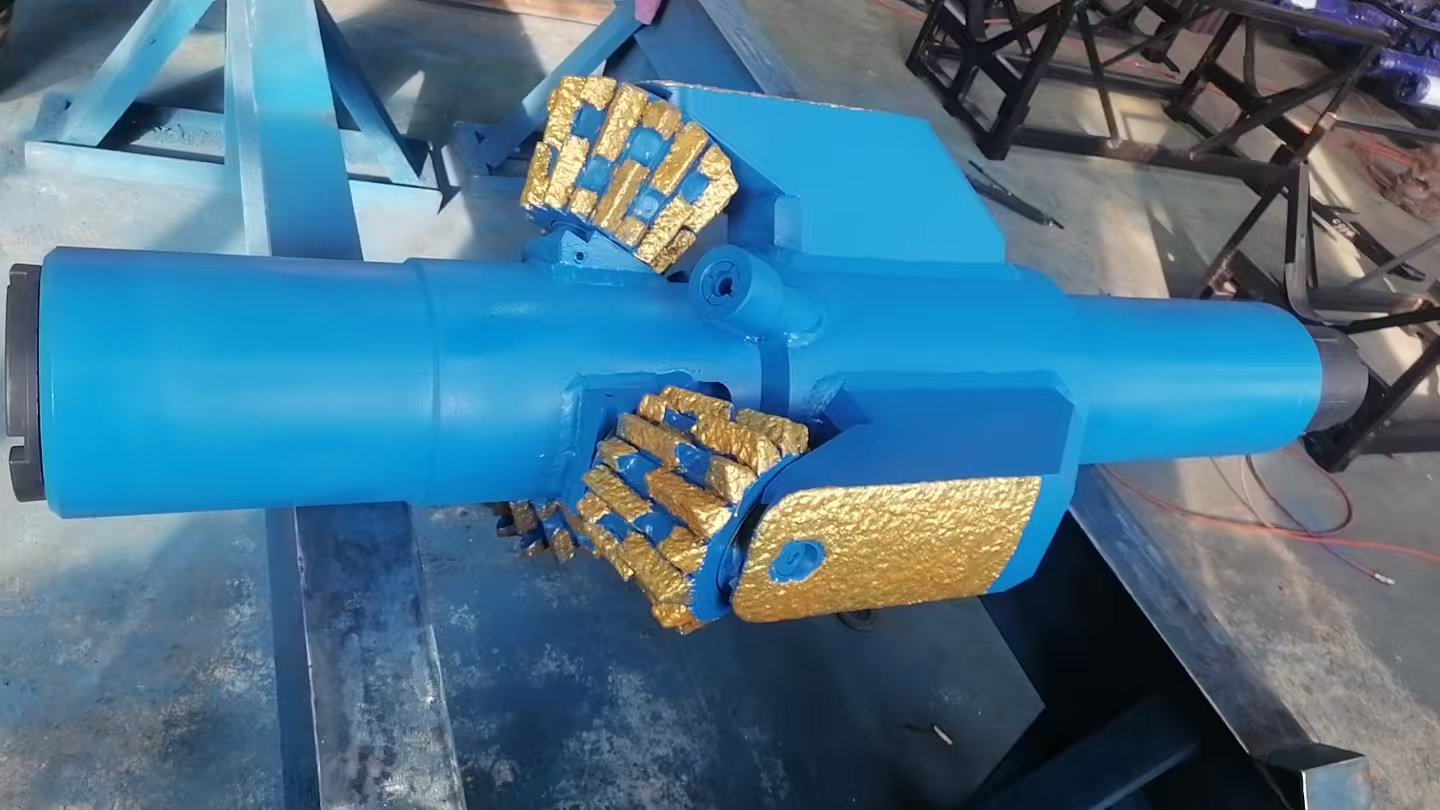

Overview of Fixed Diameter Hole Opener

Fixed Diameter Hole Openers are specialized expanding tools within Petroleum Equipment designed to reliably enlarge wellbores. They are engineered for optimal performance across a range of formations, from soft clays and shales up to medium-hard shales and limestones.

Advantages of Fixed Diameter Hole Opener

1. Superior Performance in Problem Formations: Directly addresses and mitigates balling issues in sticky shales and clays, significantly reducing downtime and frustration.

2. Increased Rate of Penetration (ROP): Continuous cleaning of the cutting structure by the jet system prevents fouling, leading to increased penetration rates and faster drilling progress.

3. Consistent Hole Diameter: As "Fixed Diameter" tools, they provide precise and reliable hole enlargement to the intended gauge size.

4. Versatile Application: Suitable for use across a wide spectrum of formation types, from soft to medium-hard, making it a valuable tool for various well sections.

5. Maintains Cutting Efficiency: The integrated cleaning jets ensure the cutters remain effective throughout the run, maximizing tool life and operational efficiency.

6. Replaceable Nozzles: Allows for customization of jetting (size, type) and easy maintenance/replacement to sustain optimal cleaning performance.

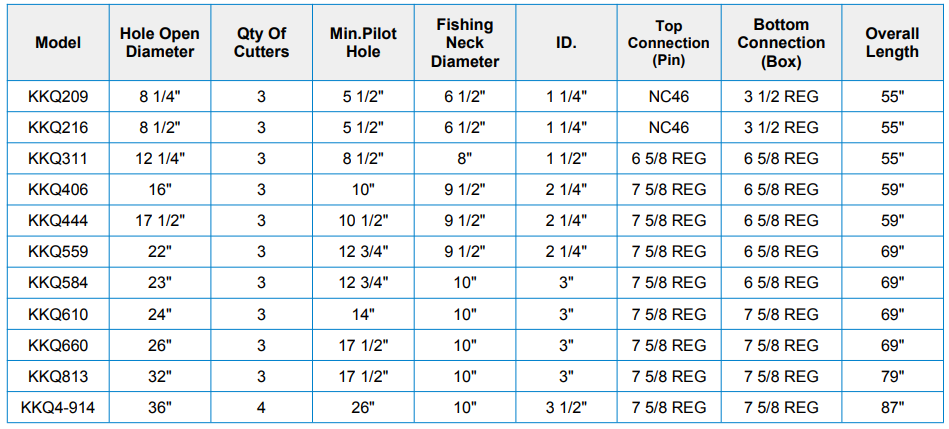

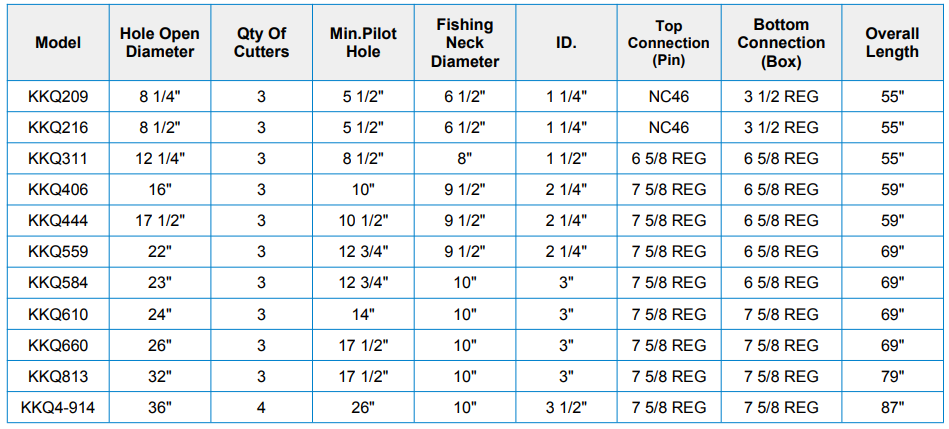

Technical parameters and customization options:

Why choose our Fixed Diameter Hole Opener?

Professional oil tools manufacturer, strictly following API standards.

Fixed Diameter Hole Opener adopts precision machining to ensure high-precision matching.

Customized service to meet the needs of different drilling conditions.

Global oil field application verification, reliability and durability are highly recognized.