Product highlights:

The roller reamer Design: Utilizes free-rotating, hardened steel rollers instead of fixed cutters or blades. This is a defining characteristic within drilling tools.

The drilling roller reamer Provides significant stabilization to the BHA, improving drilling efficiency and directional control, a key benefit of advanced expanding tools.

The drilling roller reamer reduced Friction: The rolling action significantly reduces sliding friction compared to fixed-blade tools.

Overview of drilling roller reamer:

Drilling Roller Reamer is a petroleum equipment within the broader category of oil tools used during the well construction process. It functions as a downhole stabilizer and hole opener integrated directly into the Bottom Hole Assembly (BHA). Unlike fixed-blade stabilizers or reamers, it features hardened steel rollers mounted on bearings that rotate freely as the drill string turns. Its primary purpose is to maintain or slightly enlarge the drilled hole diameter to gauge, ensure wellbore quality, stabilize the BHA, and mitigate drilling dysfunctions caused by tight spots, ledges, or minor wellbore irregularities encountered while drilling through various formations.

Advantages of Drilling Roller Reamer:

✅Superior Durability & Wear Resistance:

Drilling roller reamer ,the hardened steel rollers and bearing systems are engineered for extended life in harsh downhole environments, a major advantage for drilling tools subjected to abrasion and impact. This reduces trips for tool replacement.

✅Reduced Torque & Drag:

The rolling mechanism dramatically lowers friction against the wellbore wall compared to fixed stabilizers or reamers. This translates to lower surface torque, reduced drag, and improved weight transfer to the bit – crucial for drilling efficiency and reaching target depth.

✅Enhanced Drilling Performance & Efficiency:

As a professional downhole tools, we By minimizing friction and vibration, roller reamers contribute to smoother drilling.

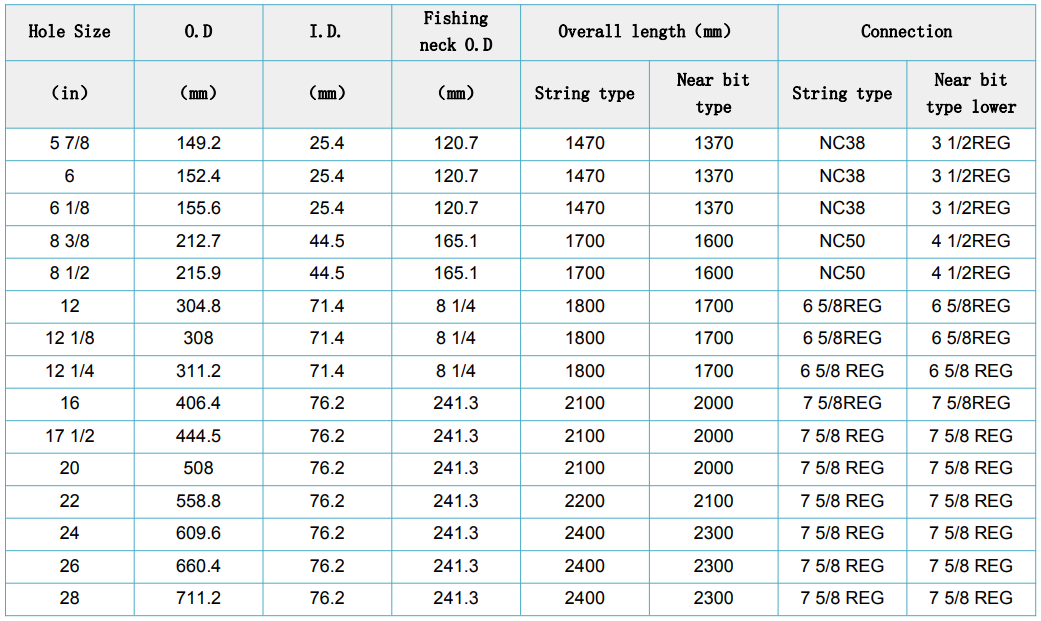

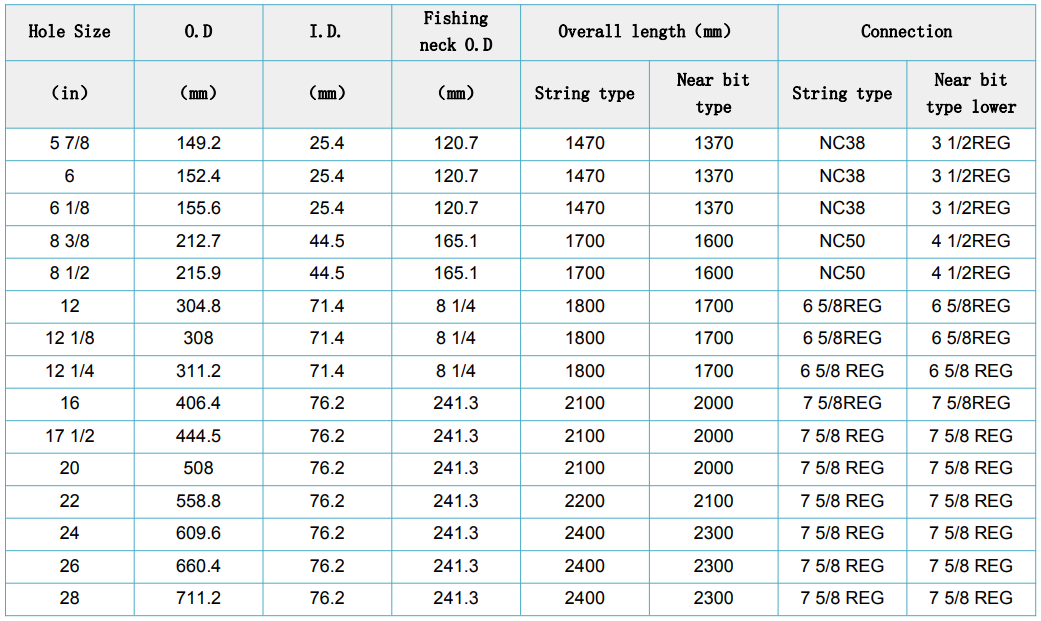

Technical parameters and customization options:

Why choose our Drilling Roller Reamer?

Professional oil tools manufacturer, strictly following API standards.

Drilling roller reamer adopts precision machining to ensure high-precision matching.

Customized service to meet the needs of different drilling conditions.

Global oil field application verification, reliability and durability are highly recognized.