Product highlights:

➤ Targeted Junk Destruction: Engineered to mill bit cones, bearings, and loose metallic objects.

➤ Centralized Milling Action: Unique concave profile traps and centers "fish" for maximum contact efficiency.

➤ Downhole Tool Protector: Prevents debris migration that damages sensitive drilling tools.

➤ Abrasion-Resistant Design: Tungsten carbide inserts (TCI) outlast standard mills 5:1.

➤ Critical Milling Tool: Integrates seamlessly with fishing tools assemblies for complex interventions.

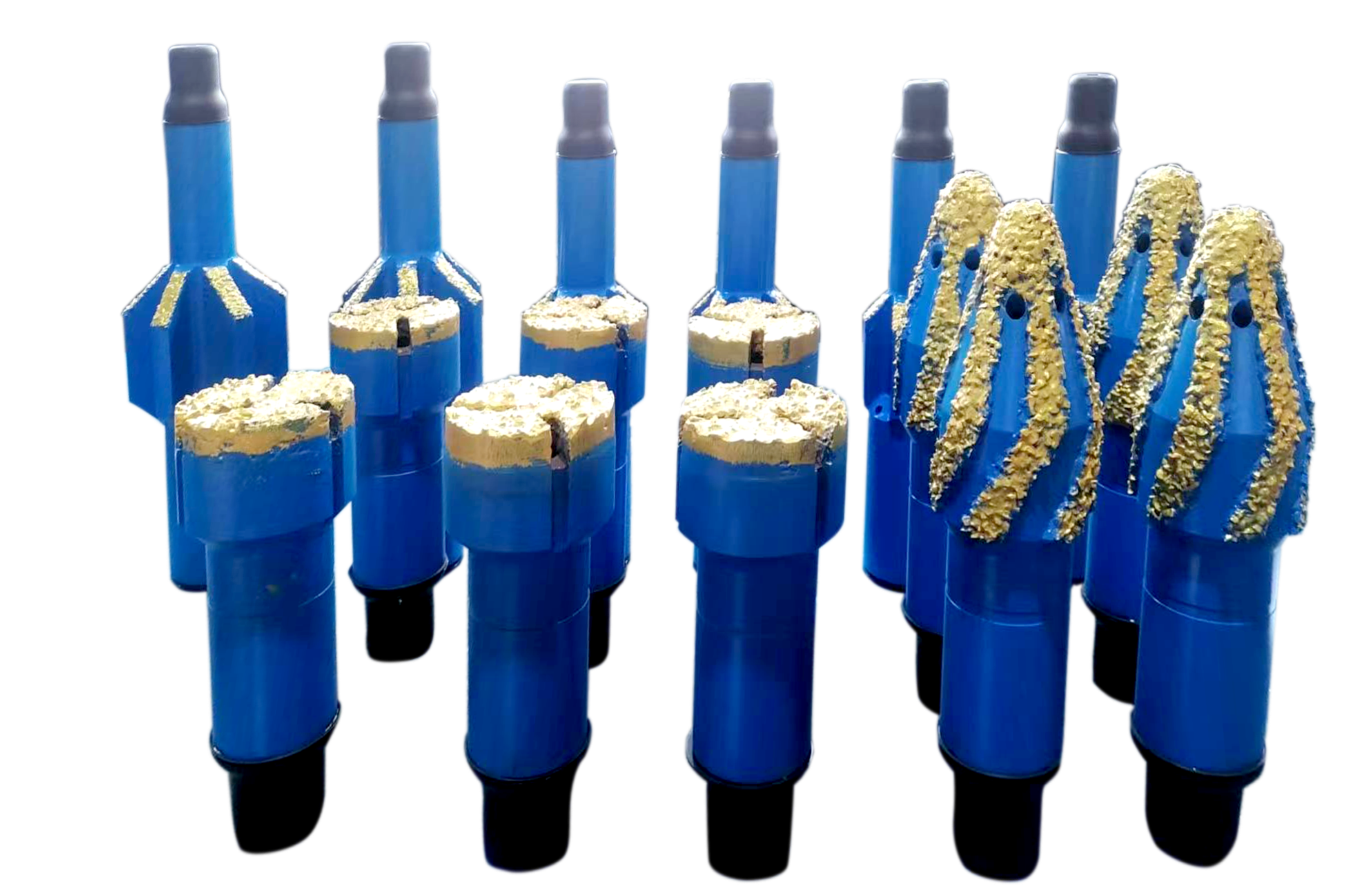

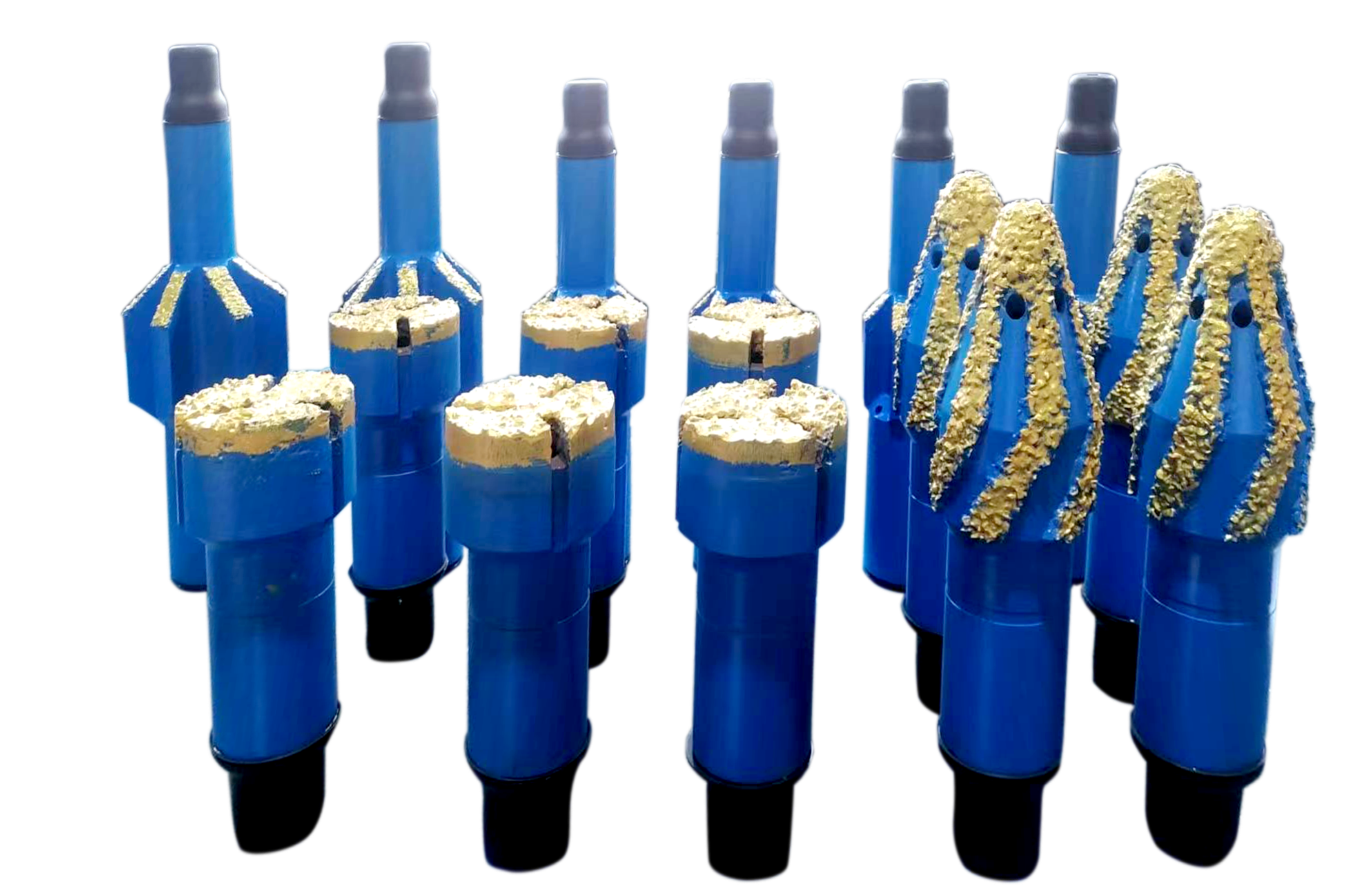

Overview of Concave Bottom Junk Mill:

The Concave Bottom Junk Mill is a specialized oil tool optimized for milling compact, rounded obstructions like bit cones that evade flat-bottom mills. Its signature dish-shaped base:

- Mechanically centralizes junk beneath the mill body

- Creates 360° cutting contact with irregular objects

- Prevents lateral escape of debris during rotation

- Maximizes WOB (weight on bit) transfer to target

Field-proven to mill stubborn metallic junk 40% faster than flat-bottom designs while protecting adjacent downhole tools from collateral damage.

Advantages of Concave Bottom Junk Mill:

1. Precision Milling Performance

- 100% Target Engagement: Concave geometry locks junk beneath cutting structure.

- Reduced Trip Time: 30% faster milling vs. flat-bottom mills (field data).

2. Downhole Equipment Safeguard

- Contains Debris: Prevents metal shards from scarring drilling tools or BHAs.

- Stabilized Operation:Minimizes lateral vibration to protect sensitive downhole tools.

3. Specialized Junk Removal

- Bit Cone Expert: Destroys hardened cone assemblies other mills cannot anchor.

- Fluid Optimization: Dual-stage circulation ports clear cuttings without clogging.

4. Engineered Longevity

- TCI Inserts: Tungsten carbide teeth rated for 200+ milling hours.

- API 7-1 Base: Compatible with all standard oil tools connections.

Why choose our Concave Bottom Junk Mill?

Professional oil tools manufacturer, strictly following API standards.

Concave Bottom Junk Mill adopts precision machining to ensure high-precision matching.

Customized service to meet the needs of different drilling conditions.

Global oil field application verification, reliability and durability are highly recognized.