Product highlights:

1. Dual-Action Jarring

Delivers powerful upward and downward impact in a single drilling jar – a critical advantage in complex wellbores.

2. Hydraulic-Mechanical Synergy

Combines robust mechanical energy storage with precision hydraulic timing for unmatched reliability in harsh conditions.

3. Engineered for Extreme Service

Forged alloy construction and wear-resistant coatings ensure longevity in demanding oil tools applications.

4. Minimal Intervention

Self-contained hydraulic system reduces field maintenance needs, maximizing rig uptime.

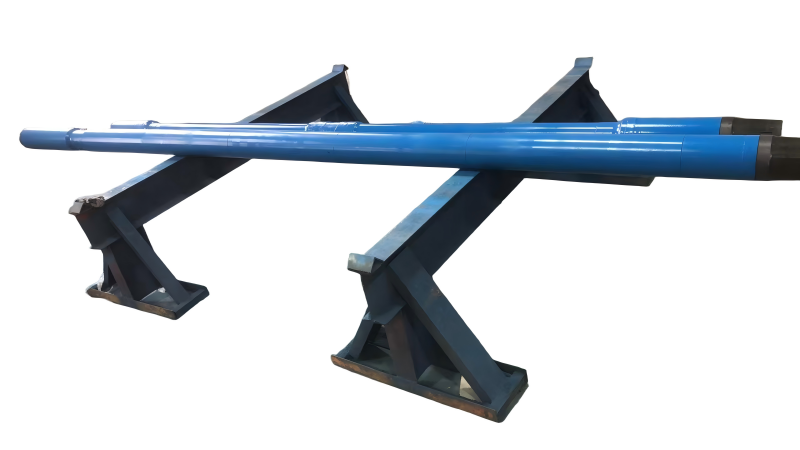

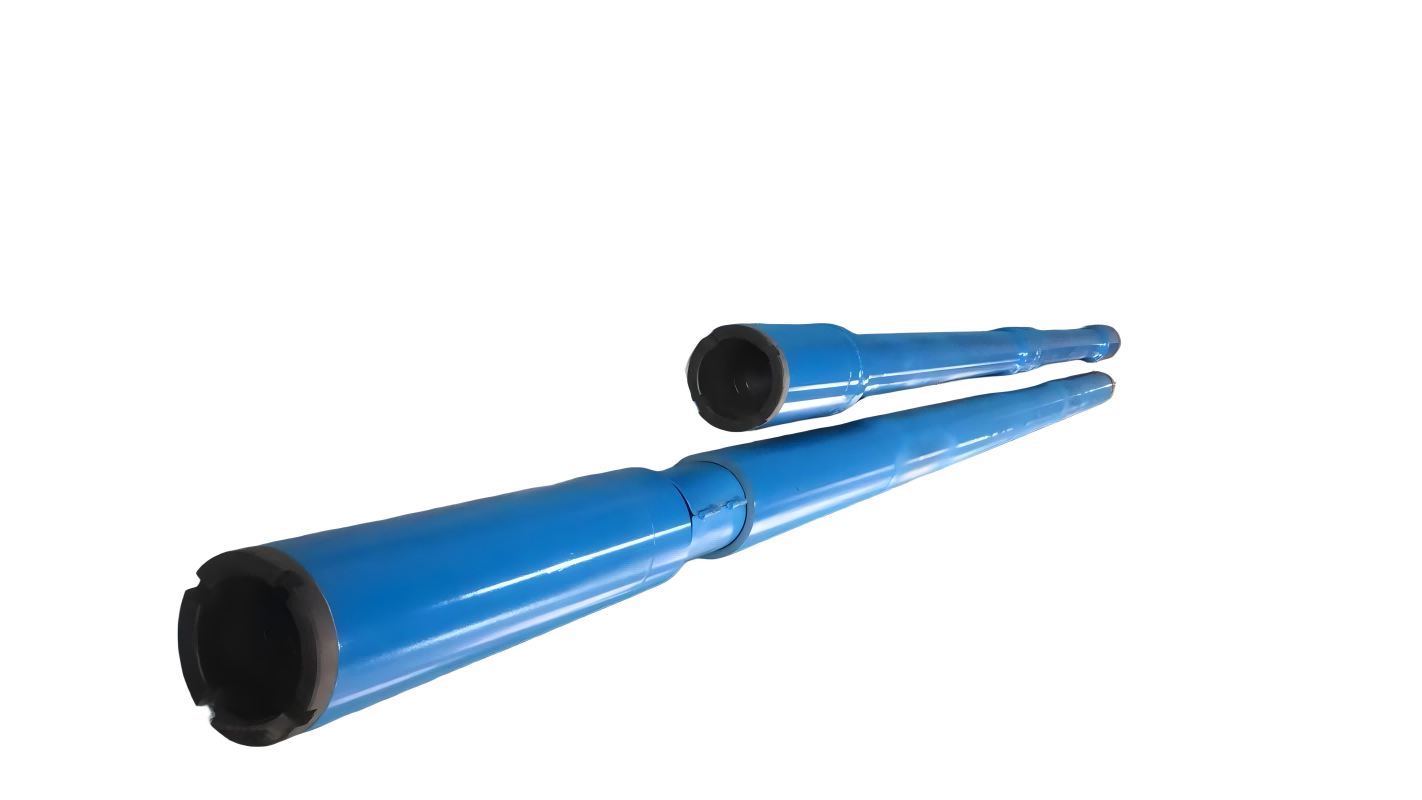

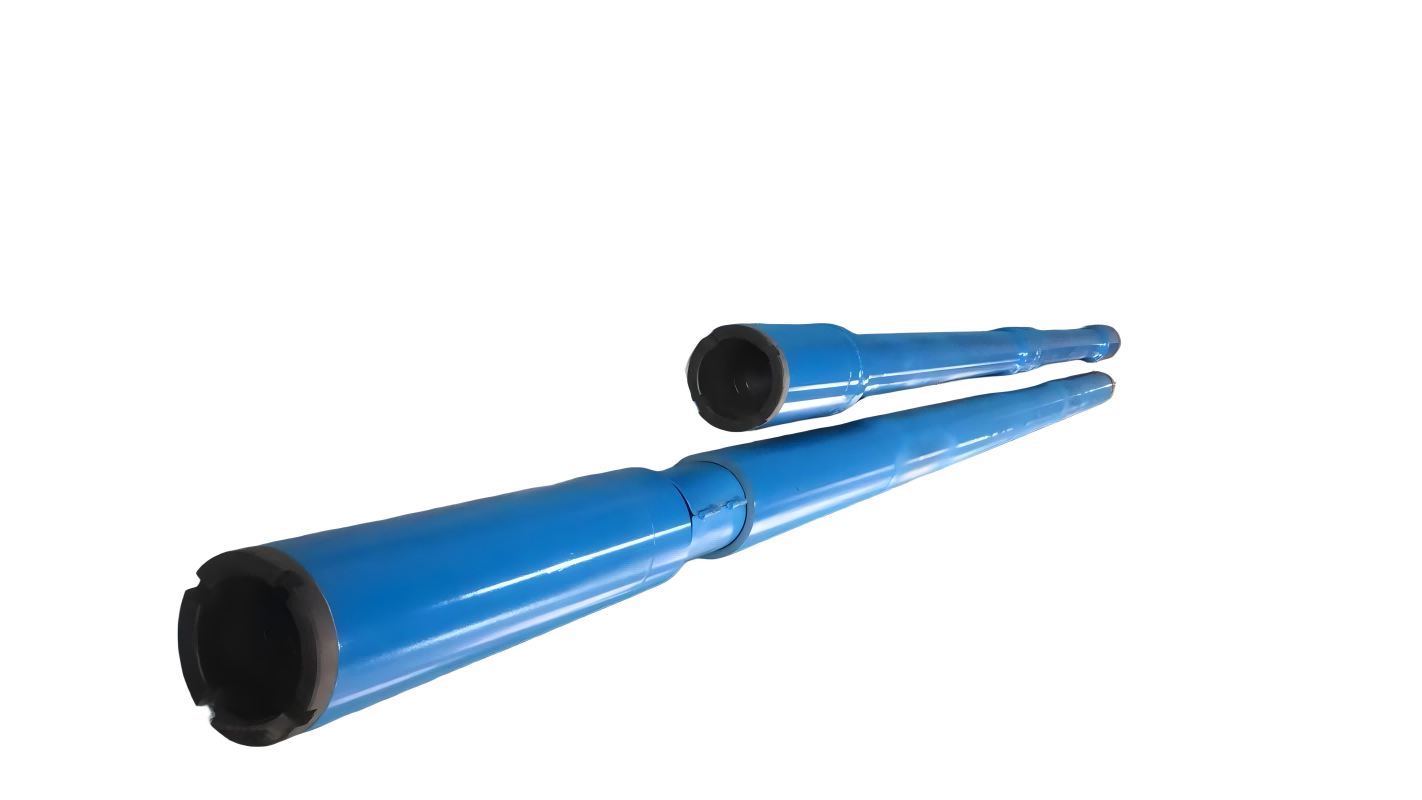

Overview of Double-Acting Hydraulic Mechanical Drilling Jar:

The drilling jar is consists of drilling up jar and drilling down jar in one body,which has stable working performance and strong jarring force both up and down.When in down hole,it can release the struck;it is a desire tool for directional well and deep well.

Advantages of Double-Acting Hydraulic Mechanical Drilling Jar:

✅ Faster Stuck-Pipe Resolution

Minimizes costly NPT by freeing pipe in minutes – outperforming conventional drilling jars.

✅ Bidirectional Versatility

Solves complex sticking (differential/keyseat) with dual-force capability – a breakthrough in drilling tools technology.

✅ Consistent Downhole Performance

Hydraulic timing ensures repeatable impact energy, unaffected by depth or fluid pressure.

✅ Reduced Operational Risk

Prevents expensive fishing jobs by addressing stuck-pipe early – enhancing safety for oil tools operations.

✅ Lower Total Cost of Ownership

Durable design + minimal maintenance cuts lifecycle costs for drilling tools.

✅ Broad Compatibility

Works with all BHA configurations and drilling fluids, ensuring flexibility as a core oil tool.

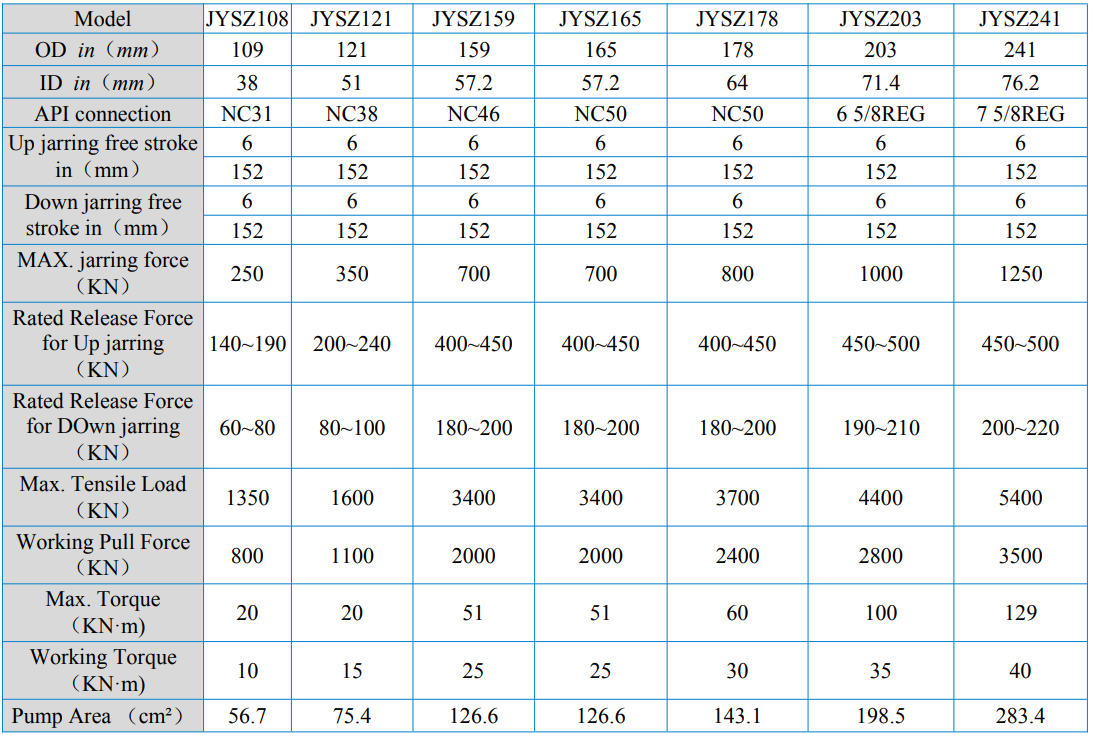

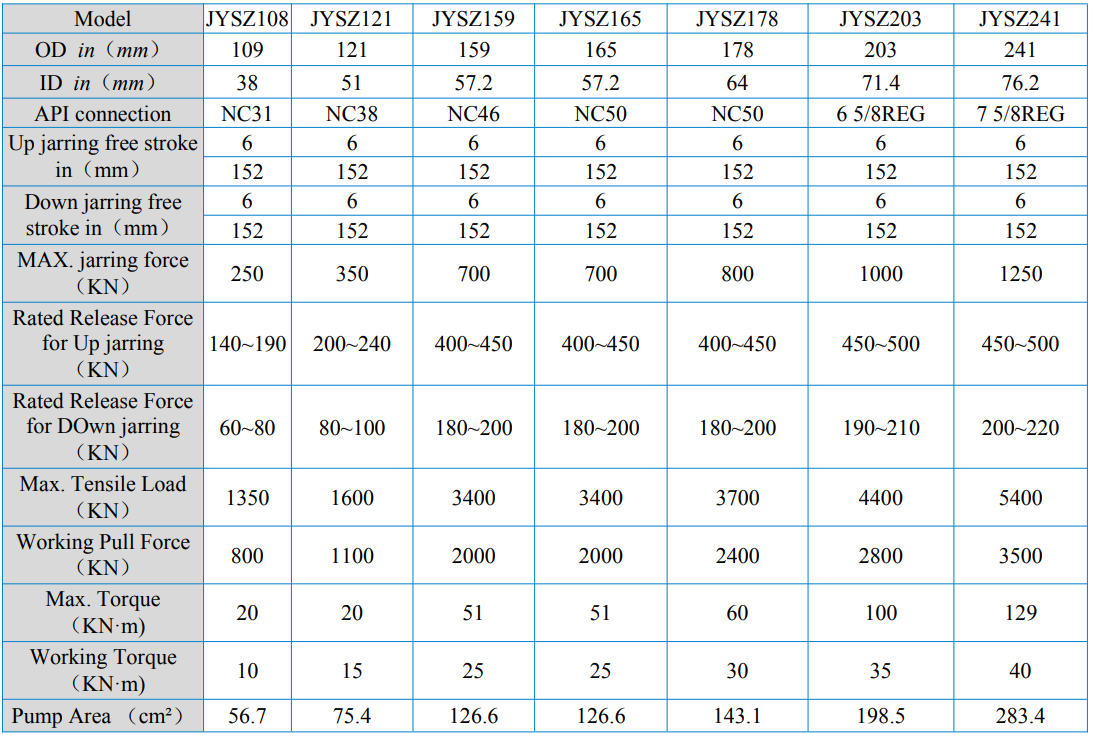

Technical parameters and customization options:

Why choose our Double-Acting Hydraulic Mechanical Drilling Jar?

Professional oil tools manufacturer, strictly following API standards.

Double-Acting Hydraulic Mechanical Drilling Jar adopts precision machining to ensure high-precision matching.

Customized service to meet the needs of different drilling conditions.

Global oil field application verification, reliability and durability are highly recognized.