Product highlights:

1. Drill Pipe Sub Optimized Pressure Containment: Designed with robust wall thickness and precise machining to withstand high internal and external pressures encountered during drilling, tripping, and well control operations.

2. Drill Pipe Sub Available in various sizes, weights, grades, and thread forms to connect different sizes/classes of drill pipe and interface with diverse drilling tools (stabilizers, reamers, jars, crossovers) within the bottom hole assembly (BHA).

3. Drill Pipe Sub Compatibility with Lifting Tools: Features standardized external upset dimensions or designated lifting areas compatible with lifting tools (e.g., elevators, spiders, handling clamps) for safe and efficient running, retrieval, and handling during rig operations.

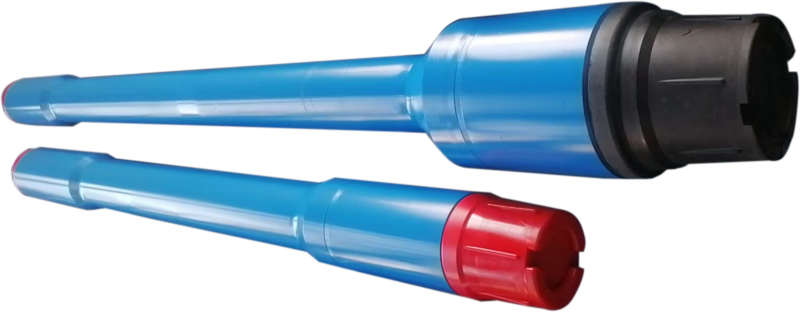

Overview of Drill Pipe Sub:

The Drill Pipe Sub is a critical, short-length connecting component within the drill string assembly. It serves as the essential interface between drill pipe joints, drilling tools (such as drill collars, heavy-weight drill pipe, or bottom hole assemblies - BHAs), and various lifting tools. Engineered to API (American Petroleum Institute) specifications or higher, this robust forged component ensures a secure, pressure-tight, and high-strength connection, transmitting torque, weight, and fluid flow reliably under extreme downhole conditions. It is a fundamental element in any drilling operation's tool string.

Advantages of Drill Pipe Sub:

1. Enhanced Drill String Reliability: Minimizes connection failures by providing a robust, high-integrity link between drill pipe segments and critical drilling tools, reducing costly downhole incidents and non-productive time (NPT).

2. Maximized Torque & Load Transfer: Engineered to efficiently transmit high rotational torque and axial loads (compression & tension) throughout the drill string, enabling efficient drilling performance and weight transfer to the bit.

3. Superior Fatigue Life: Advanced metallurgy and manufacturing processes significantly increase resistance to cyclic stresses, extending service life and reducing replacement frequency compared to standard components.

4. Improved Safety: Secure connections prevent accidental disconnection or thread jump-out under load. Compatibility with standard lifting tools ensures safer handling procedures during tripping and assembly on the rig floor.

5. Operational Efficiency: Ensures smooth drilling fluid flow and reliable connection make-up/break-out, contributing to faster tripping speeds and overall operational efficiency. Reduces the risk of washouts or leaks at connection points.

6. Reduced Total Cost of Ownership (TCO): While a premium component, its extended lifespan, reduced failure rates, and contribution to minimizing costly downtime lead to a lower overall cost per foot drilled.

Why choose our Drill Pipe Sub?

Professional oil tools manufacturer, strictly following API standards.

Drill Pipe Sub adopts precision machining to ensure high-precision matching.

Customized service to meet the needs of different drilling conditions.

Global oil field application verification, reliability and durability are highly recognized.