Product highlights:

1. Drilling Tools Compatibility

- Universal design fits drill collars, HWDP, casing, and BHA components across sizes (2-3/8" to 9-5/8").

- Interchangeable inserts adapt to thread profiles (box/pin) without tooling changes.

2. Ruggedized Durability

- Hardened surfaces resist abrasion from rig-floor debris and repeated lifting tool contact.

- Anti-galling coating on mating threads extends service life.

3. Operational Efficiency

- Quick-install design (<10 sec) via hammerless latch mechanisms - no wrenches required.

- Ergonomic handling features (forklift pockets, roll-resistant base) for rig crew safety.

Overview of Lifting Cap:

The Lifting Cap (PLUG) is an essential safety and handling component engineered for rig-floor operations. Designed as a robust thread protector and lifting interface, it safeguards critical connections on drill pipe, casing, and bottom hole assemblies (BHAs) while enabling secure engagement with lifting tools (e.g., elevators, bails, hoists). Manufactured to API/ISO standards, this dual-purpose petroleum equipment prevents thread damage, contamination, and dropped-object hazards during tripping, storage, and transport of tubulars.

Advantages of Lifting Cap:

✅ Eliminates Tubular Damage

> Protects drilling tools** from thread dents/cross-threading, reducing rework costs by 90%.

✅ Accident Preventio

> Secures tubulars during vertical lifts, eliminating drops caused by slipped slings or damaged threads.

✅ Rig Floor Productivity

> Cuts tripping time 15% by enabling direct hoist attachment - no sling re-rigging between lifts.

✅ Corrosion Control

> Sealed O-ring/gasket design blocks moisture, mud, and H₂S ingress during storage/transport.

✅ Asset Longevity

> Extends tubular service life 2-3x by preventing connection wear and stress concentrations.

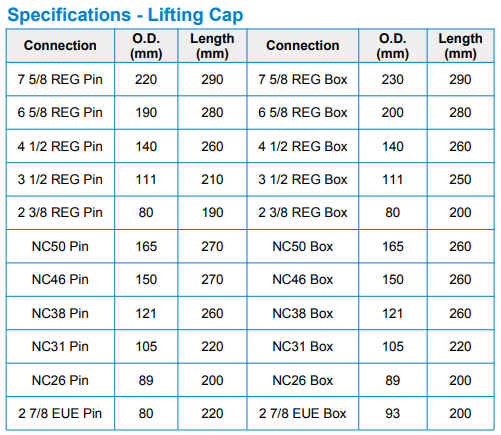

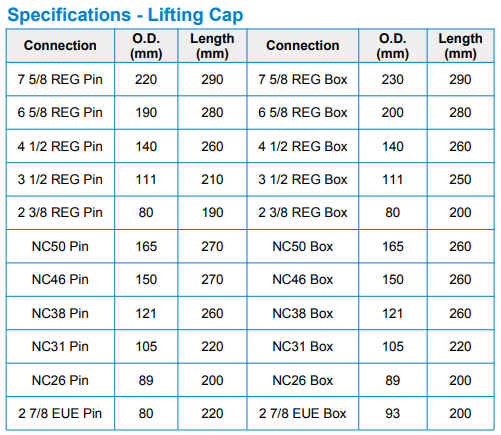

Technical parameters and customization options:

Why choose our Lifting Cap?

Professional oil tools manufacturer, strictly following API standards.

Lifting Cap adopts precision machining to ensure high-precision matching.

Customized service to meet the needs of different drilling conditions.

Global oil field application verification, reliability and durability are highly recognized.