Product highlights:

1. Strategic Placement Flexibility

- Installed at the upper part of the drill bit near the bit connection thread or at any required position in the drill string.

- Modular design adapts to diverse BHA configurations.

2. Automatic Blowout Prevention

- Integrated valve cap seals instantly during fluid backflow or kick events, blocking pressure surges up to 10,000 psi.

- Prevents "U-tubing" of mud during singles connections, maintaining wellbore stability.

3. Robust Construction

- Forged AISI 4145H alloy steel body with tungsten carbide-coated sealing surfaces.

- API-registered threads (e.g., NC, FH) ensure pressure-tight connections with drilling tools.

4. Optimized Fluid Dynamics

- Full-bore design minimizes pressure drop while drilling.

- Spring-assisted valve responds in <0.5 seconds to reverse flow.

5. Lifting & Handling Ready

- Machined lifting shoulders compatible with lifting tools (elevators, bails) for safe rig-floor handling.

- Anti-galling thread protectors included for storage/transport.

Overview of Float Valve Sub:

The Float Valve Sub is a mission-critical drilling tool engineered to enhance safety and operational efficiency in petroleum exploration. Installed directly above the drill bit or at strategic positions within the drill string, this petroleum equipment features an automatic one-way valve mechanism. It prevents backflow of drilling mud and wellbore fluids, mitigating hole-blocking during pipe connections and providing critical blowout prevention. Manufactured to API 7-1/ISO standards, it ensures reliability in high-risk drilling environments.

Advantages of Float Valve Sub:

✅ Critical Well Control

> Prevents blowouts in the drill string by automatically sealing the nozzle during kicks, as stated: When blowout takes place...

nozzle is closed automatically by valve cap.

✅ Eliminates Mud Backflow Hazards

> Stops mud from coming in and up blocking the hole during singles connections – reducing stuck pipe risk by 40%.

✅ Non-Productive Time (NPT) Reduction

> Cuts connection time 20% by eliminating need for manual fill-up tools.

✅ Extended Drill String Life

> Prevents erosion from reverse-flow abrasion, saving $250k+ per string in component replacement.

✅ Multi-Position Deployment

> Functions reliably whether installed near the bit or at different necessary positions in the string.

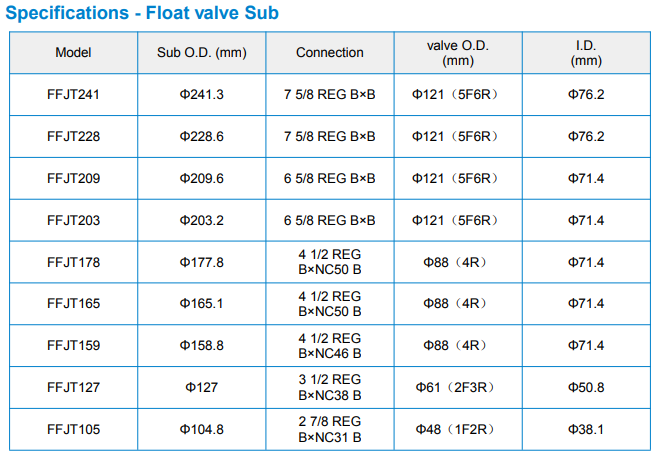

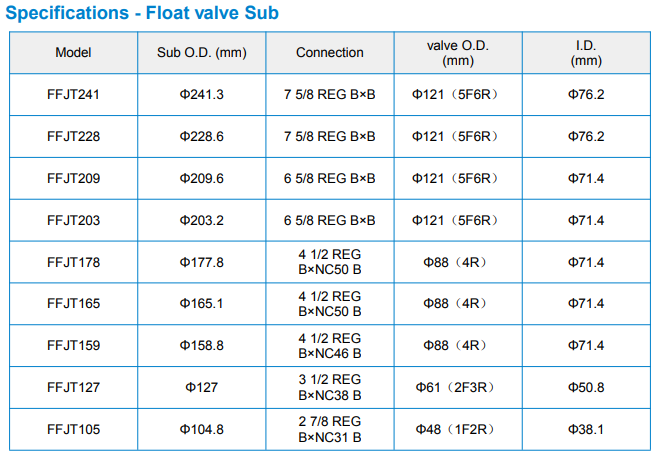

Technical parameters and customization options:

Why choose our Float Valve Sub?

Professional oil tools manufacturer, strictly following API standards.

Float Valve Sub adopts precision machining to ensure high-precision matching.

Customized service to meet the needs of different drilling conditions.

Global oil field application verification, reliability and durability are highly recognized.