Product highlights:

● Mechanical properties and design of drill pipe joints, pipe bodies, and weld zones conform to the latest API SPEC 5DP and RP 7G standards;

● Wear-resistant hardfacing can be applied to the box-end connection;

● Threads at both ends undergo phosphate coating and are equipped with thread protectors;

● Cold rolling treatment can be performed at the thread roots of both ends;

● Threads at both ends can undergo makeup/breakout testing.

Overview of Drill Pipe:

Ordinary drill pipes are tubular components in drilling tools that connect the drill bit, transport drilling fluid, and transmit power. They must withstand significant internal/external pressure, torsion, bending, and vibration. Drill pipes can be reused multiple times during oil and gas extraction and refining. They are classified into three types: square drill pipes, drill pipes, and heavy-weight drill pipes. The connection sequence is: square drill pipe (1 unit) + drill pipes (n units, determined by well depth) + heavy-weight drill pipes (n units, determined by drilling assembly design).

The drill pipes produced by our company comply with the SY/T5561 and API Spec 5DP standards. To reduce wear on casings and drill pipes, wear-resistant hardfacing can be applied to the box-end connection of the drill pipe.

Advantages of Drill Pipe:

✔ API-Compliant Design– Mechanical properties of drill pipe joints, pipe bodies, and weld zones meet API SPEC 5DP & RP 7G standards.

✔ Extended Lifespan – Wear-resistant hardfacing reduces wear on connections, lowering operational costs.

✔ Superior Thread Protection – Phosphate-coated threads and thread protectors prevent damage during handling and storage.

✔ Advanced Fatigue Resistance– Optional cold rolling treatment strengthens thread roots, enhancing durability.

✔ Reliable Performance – Pre-tested connections ensure stability in high-stress drilling environments.

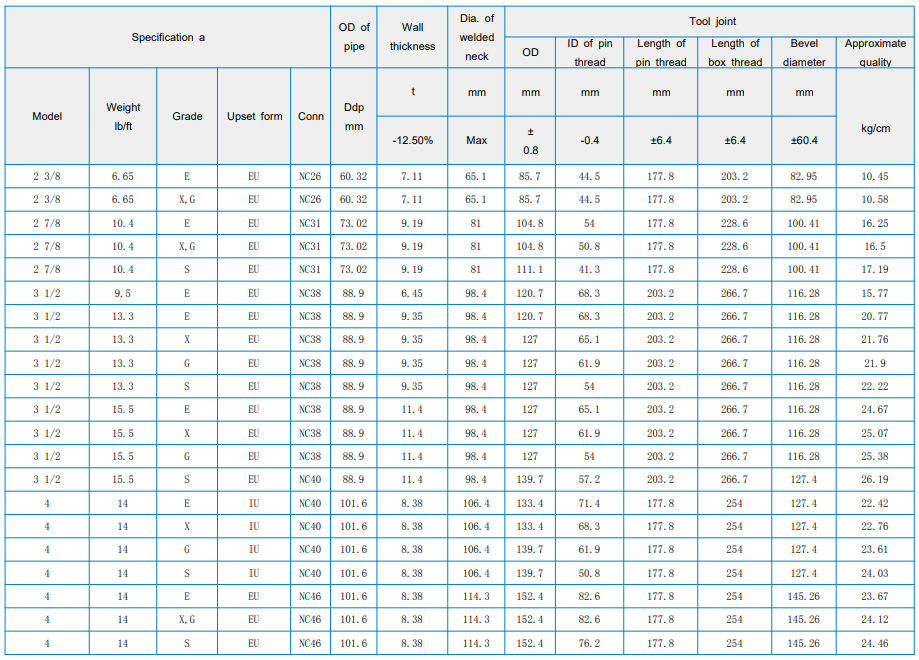

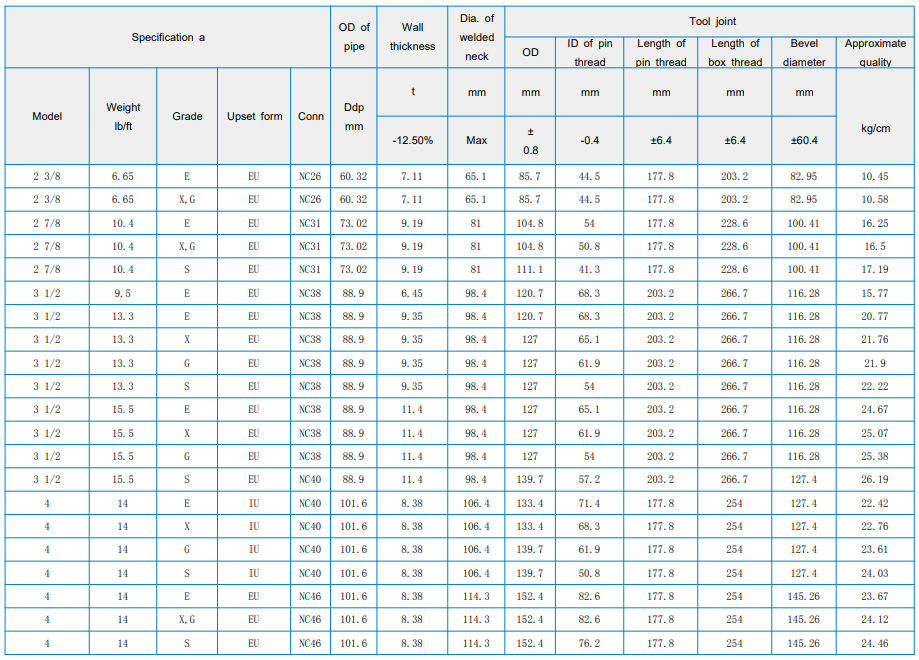

Technical parameters and customization options:

Why choose our Drill Pipe?

Professional oil tools manufacturer, strictly following API standards.

Drill Pipe adopts precision machining to ensure high-precision matching.

Customized service to meet the needs of different drilling conditions.

Global oil field application verification, reliability and durability are highly recognized.