Product highlights:

Premium Performance for Demanding Drilling Applications

- Manufactured from AISI 4145H modified quenched & tempered steel for superior strength and durability

- Spiral groove design reduces wall contact by up to 40%, minimizing differential sticking risks

- Full-length heat treatment ensures uniform hardness (285-341 HBW) and toughness (40 ft-lbs Charpy impact)

- Cold-rolled thread roots on API and H-90 connections enhance fatigue resistance

Engineered for Optimal Downhole Performance

- Phosphate-coated connections prevent corrosion and thread galling

- Pressed steel thread protectors included for all standard connections

- Available in standard and non-magnetic configurations

- Reduced hydrostatic pressure due to spiral grooves improves drilling efficiency

Rigorous Quality Assurance

- Strict metallurgical testing at 16 points per cross-section

- Compliant with API specifications for BHA components

- Ultrasonic inspection available upon request

Overview of Spiral Drill Collar:

The Spiral Drill Collar is an enhanced version of the standard drill collar, featuring helical grooves along its length to optimize

performance in challenging drilling conditions. As a critical downhole tool in the Bottom Hole Assembly (BHA), it provides essential

weight on bit (WOB) while maintaining drill string tension.

XINRUIDE Spiral Drill Collars combine the fundamental strength of traditional drill collars with advanced spiral geometry that reduces

wall contact area. This innovative design significantly decreases the risk of differential sticking while maintaining all the benefits of our

premium AISI 4145H modified steel construction.

Advantages of Spiral Drill Collar:

✔ Reduced Sticking Risk - Spiral grooves minimize wall contact area by 40% compared to smooth collars

✔ Enhanced Drilling Efficiency - Lower hydrostatic pressure improves ROP (Rate of Penetration)

✔ Superior Material Strength - 285-341 HBW hardness with 40 ft-lbs impact resistance

✔ Corrosion Protection - Phosphate coating on all connections

✔ Extended Service Life - Cold-rolled threads and premium materials reduce fatigue failures

✔ Versatile Applications - Effective in directional drilling and high-angle wells

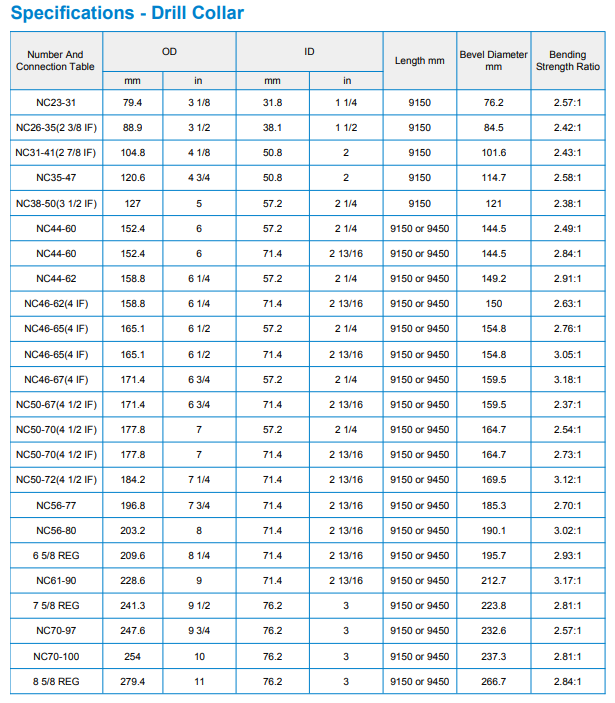

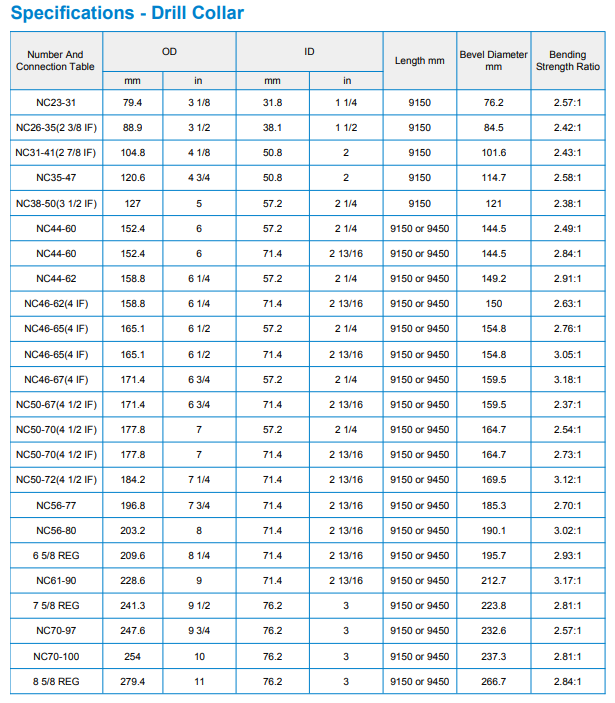

Technical parameters and customization options:

Why choose our Spiral Drill Collar?

Professional oil tools manufacturer, strictly following API standards.

Spiral Drill Collar adopts precision machining to ensure high-precision matching.

Customized service to meet the needs of different drilling conditions.

Global oil field application verification, reliability and durability are highly recognized.