Product highlights:

Superior Strength & Durability

- Manufactured from AISI 4145H modified quenched & tempered steel for maximum hardness and toughness.

- Full-length heat treatment ensures uniform strength and durability throughout the entire drill collar.

- Guaranteed hardness range (285-341 HBW) and Charpy impact value (40 ft-lbs) for reliable performance in harsh drilling conditions.

Precision Engineering & API Compliance

- Phosphate-coated connections prevent corrosion and galling during initial makeup.

- Cold-rolled thread roots on API and H-90 connections for enhanced fatigue resistance.

- Pressed steel thread protectors included for all standard connections to ensure damage-free handling.

Rigorous Quality Assurance

- Strict metallurgical testing ensures consistent hardness and structural integrity.

- Certified to meet API specifications for optimal performance in Bottom Hole Assembly (BHA) applications.

Overview of Standard Drill Collar:The Drill Collar is a fundamental downhole tool and a critical component of the Bottom Hole Assembly (BHA). It provides weight on bit (WOB) for efficient drilling while maintaining tension in the drill string.

XINRUIDE Drill Collars are engineered for extreme drilling environments, offering superior strength, stability, and fatigue resistance.

Their robust construction ensures reliable performance in both vertical and directional wells.

Advantages of Standard Drill Collar:

✔ High-Strength Alloy Steel – Made from AISI 4145H modified steel, heat-treated for maximum hardness (285-341 HBW) and impact resistance (40 ft-lbs).

✔ Full-Length Heat Treatment – Ensures uniform toughness along the entire length for long-lasting durability.

✔ Corrosion-Resistant Connections – Phosphate-coated threads prevent galling and corrosion.

✔ Enhanced Fatigue Resistance – Cold-rolled thread roots extend service life under high-stress conditions.

✔ Thread Protection – Pressed steel thread protectors safeguard connections during transport and storage.

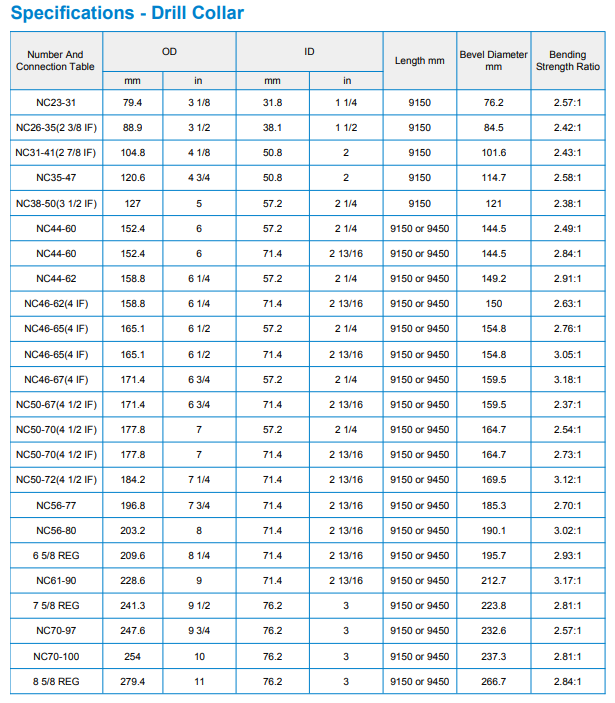

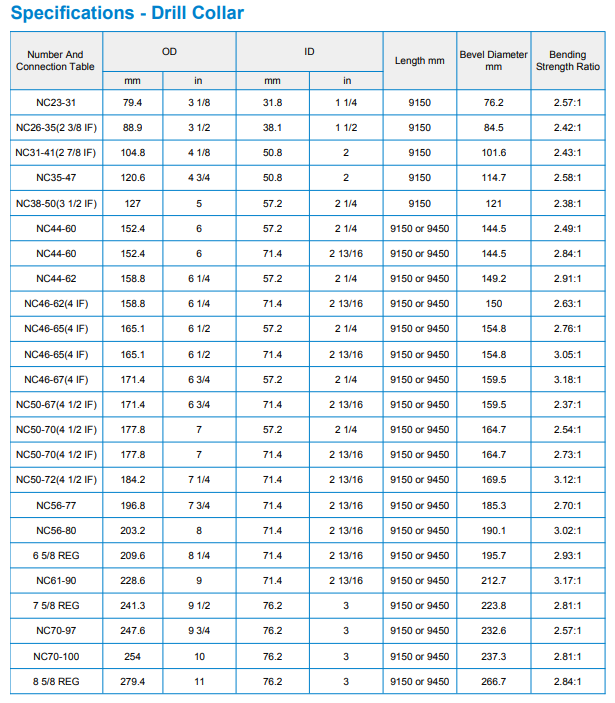

Technical parameters and customization options:

Why choose our Standard Drill Collar?

Professional oil tools manufacturer, strictly following API standards.

Standard Drill Collar adopts precision machining to ensure high-precision matching.

Customized service to meet the needs of different drilling conditions.

Global oil field application verification, reliability and durability are highly recognized.