Product highlights:

Premium Quality & Precision Engineering

- Manufactured from AISI 4145H-modified alloy steel, fully heat-treated for superior strength and durability.

- Brinell hardness range: 285-341 BHn, with a minimum Charpy impact value of 40 ft-lbs for high toughness.

- Precision-milled flats to API specifications, ensuring optimal torque transmission.

- Ultrasonic inspection performed on all sections for defect-free reliability.

Rigorous Manufacturing Standards

- Straightness inspections conducted before, during, and after machining to guarantee perfect alignment.

- Threads and connections machined and inspected to API specifications for seamless integration with drill pipes and downhole tools**.

- Pressed steel thread protectors included to safeguard connections during transport and handling.

Enhanced Protection & Longevity

- Shipped in a protective steel-cased scabbard to prevent damage during transit.

- Designed for high torsional strength, ensuring efficient power transfer from the rotary table to the drill string.

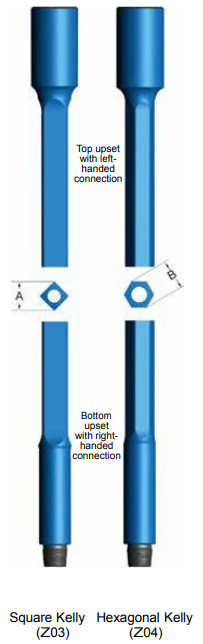

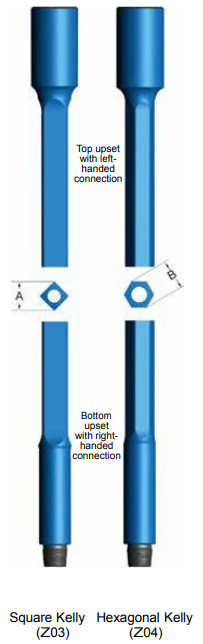

Overview of Square Kelly:

Kelly is main driver of the whole drill string. It transmits torsional energy from therotary table through the drill string to the bit at the bottom of the hole. XINRUIDE Kelly is a long square or hexagonal, precision machined heavy steel bar that issupported by the swivel through the rotary table and is connected to the first jointof drill pipe in the drill string. Straightness of the kelly is very crucial in the manufacturing process, thusstraightness inspections are carried out before, during and after each machiningoperation. The flats are precision-milled to API specifications. All milling processesare performed on specially designed rigid Kelly mills to ensure tight tolerances andhigh quality drive sections. Each XINRUIDE Kelly is furnished with a pressed steelthread protectors.

Advantages of Square Kelly:

✔ High-Strength Alloy Steel – Made from AISI 4145H-modified steel, heat-treated for maximum durability and fatigue resistance.

✔ API-Compliant Machining – All drive sections, IDs, and connections meet API standards for seamless compatibility with downhole tools.

✔ Precision Straightness Control – Inspected at every stage to ensure optimal performance in demanding drilling conditions.

✔ Superior Impact Resistance – Minimum 40 ft-lbs Charpy impact value for reliable operation under high stress.

✔ Enhanced Protection – Steel-cased scabbard and thread protectors prevent damage during shipping and storage.

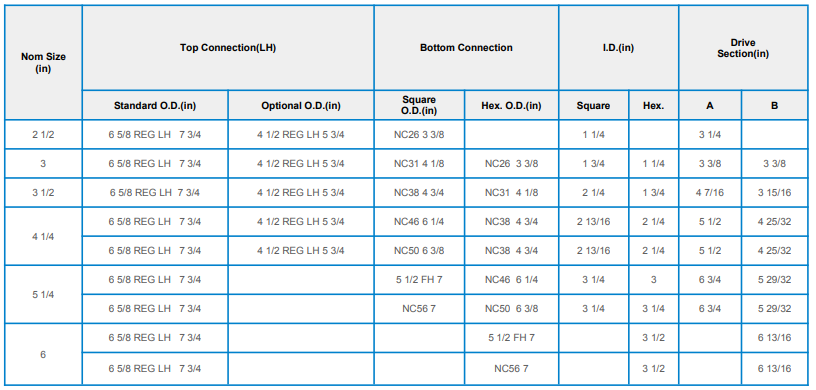

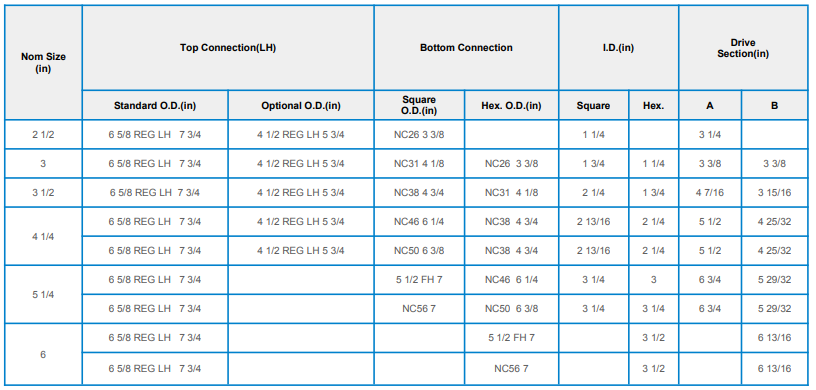

Technical parameters and customization options:

Why choose our Square Kelly?

Professional oil tools manufacturer, strictly following API standards.

Square Kelly adopts precision machining to ensure high-precision matching.

Customized service to meet the needs of different drilling conditions.

Global oil field application verification, reliability and durability are highly recognized.